engineering solutions for your business

Experienced reliable and innovative solutions for your engineering needs.

WHO WE ARE

Our Vision

Providing Manufacturing Solutions for a Dynamic World

Our goal is to offer manufacturing solutions that cater to an ever-changing world that we all share. We achieve innovation through simplifying designs, and tackling the most complex challenges head-on. Our pursuit of perfection is fueled by precision, ensuring that our solutions are of the highest quality.

Our Mission

We believe in providing personalised service to our customers, recognising that no two businesses are identical. Regardless of the size of your business, we understand that time is a valuable commodity. Therefore, we strive to deliver honest and cost-effective solutions within the tight manufacturing timelines that our clients often face.

History

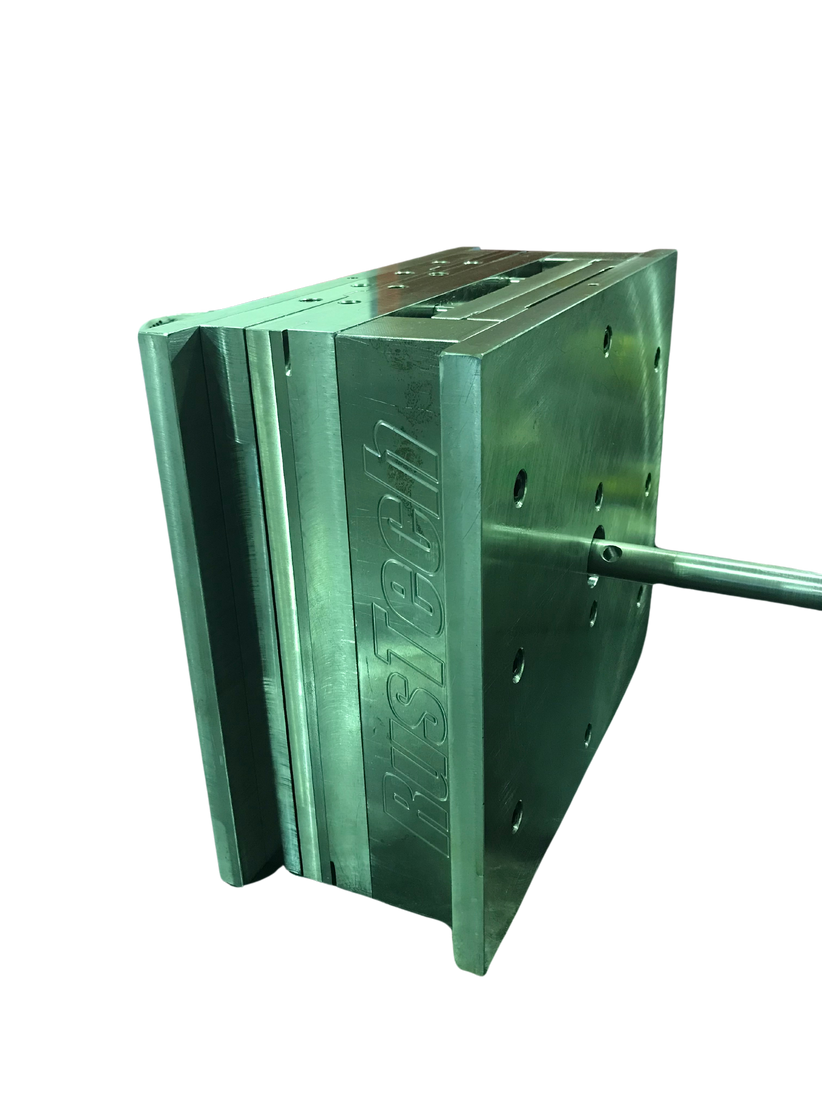

Russell's father, who emigrated from Austria to South Africa, was a Toolmaker, and this craft runs in their family. Russell started his Tool-making career in 2008, immediately after finishing school at Westville Boys’ High School. He began his apprenticeship in Tool, Jig, and Die making and had a successful career until he decided to establish his own business in 2016. In the same year, his father retired and joined Rustech, and together, they grew the company from one little leadwell CNC milling machine to its current state.

Initially, the company started with a only two customers, but through hard work and dedication, they grew the business machine by machine and customer by customer. They expanded their conventional workshop with lathes and turret milling machines and brought in two more CNC milling machines. As a result, they now house Hartford machining centers, Welltec plastic injection moulding machines, and a Surface grinder that caters to plate sizes up to 1 meter by 400mm. Additionally, they handle all in-house TIG welding on both aluminum and steel in order to refurbish Tooling.

Why work with us

Customers recognise us for our flexibility and specialisation

Rustech has been acknowledged for providing a steady stream of high-quality products.

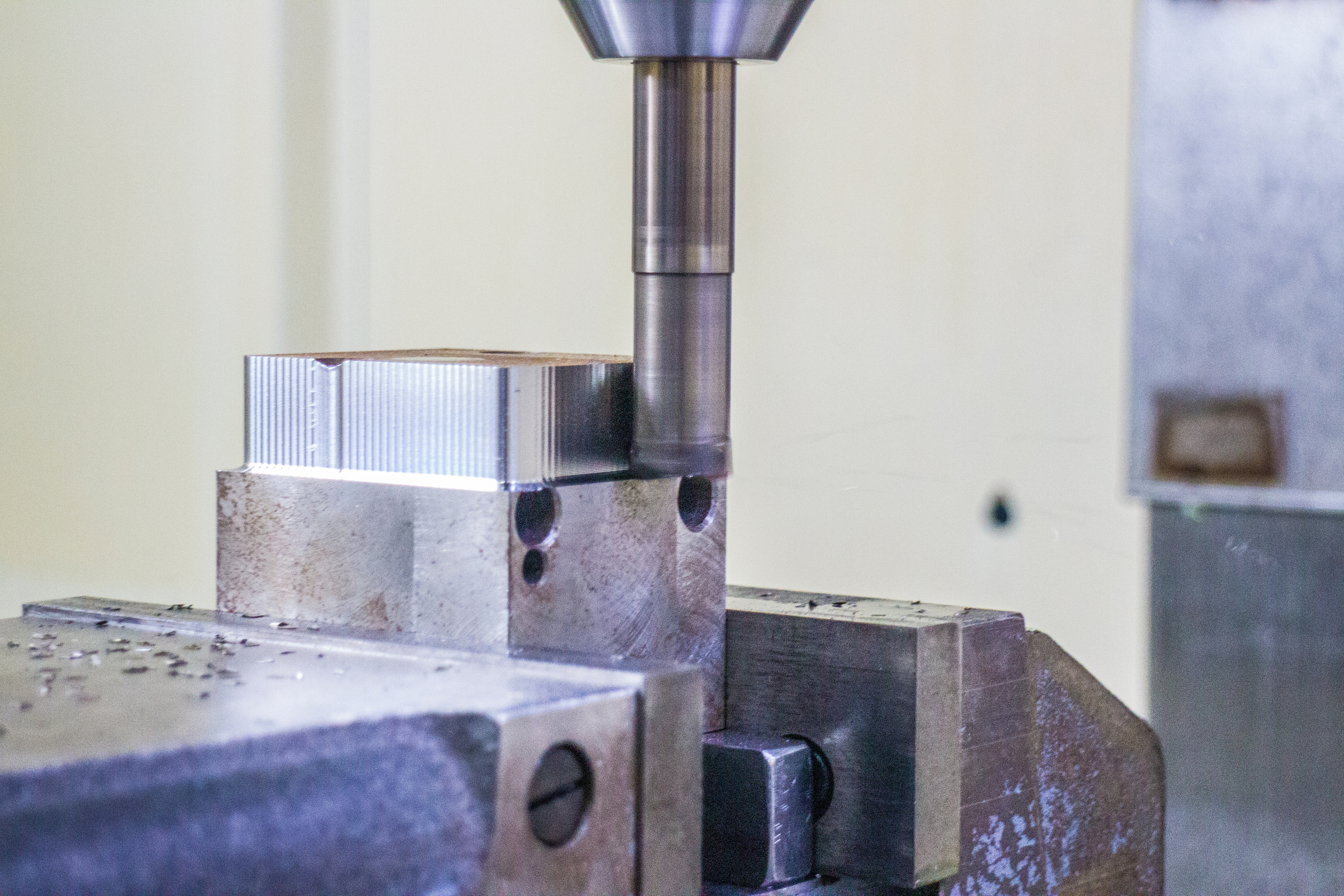

Our state-of-the-art equipment enables us to apply cutting-edge techniques to our manufacturing process.

Our expertise lies in turning creative ideas into tangible realities. We provide precision engineering services, enabling us to manufacture and design machine parts, jig fixtures, moulds and assembly components with accuracy and efficiency. Whether it's repairing machine parts or creating bespoke components, we're equipped to handle all your engineering and Tool making needs.

Tool, Jig & Die Making

We specialise in servicing and repairing various types of tooling, including rubber compression and injection moulds. Our expertise also encompasses the refurbishment of plastic injection and blow moulds, as well as manufacturing machine parts such as knifing tools and assembly jigs. Our services include welding, redesigning, and remachining to restore these tools to optimal working condition.

Specialising in cutting-edge technology, our company delivers efficient mould and fixture production that streamlines the manufacturing and packaging processes in South Africa.

CNC Machining

We offer in-house precision grinding on plate sizes up to 1 meter by 400mm.

Our company specialises in creating computer-aided designs. Through 3D modelling, we can transform any product, mould, or idea into a tangible and printable object. Our expertise extends to product and mould design, as well as modifications to existing models. Our team utilises CAD software to create all our models. Additionally, we can automate the designs to demonstrate their functionality.

After you've made the wise decision to invest in a new Rustech tool, consider allowing us to manage your production process. Our injection molding machines are equipped with the latest servo technology, and we pride ourselves on being a cost-effective solution. Although we are not currently ISO certified, we adhere to ISO standards.

All Types of Moulds and Dies for Your Business Needs

We design and manufacture:

- Plastic injection moulds (with and without hot-runner systems)

- Rubber and silicon moulds (both injection and compression types)

- Plastic blow moulds (both PET and extrusion HDPE Blow moulds)

- Head tooling to services your extrusion blow moulding (including overlized head tooling)

- Extrusion Die-heads

ContacT US

Email us and we will be in contact!

hours

Monday - Friday 08:00 - 17:00

Copyright

2023 Rustech Tool and Design - All Rights Reserved

Powered by KC Marketing Solutions